In a world of cabinetry, tool storage, and industrial equipment, the unsung heroes ensuring smooth functionality are high-strength drawer slides. The selection of these vital components can significantly impact the durability and efficiency of your drawers. Due to all that is needed to choose a perfect drawer slide, this guide will assist you in making an informed decision when choosing high-strength drawer slides for your project.

In this article, we’ll take a better look at some of the considerations, including load capacity, slide types, materials, installation nuances, and the delicate balance between cost and quality.

The Ins and Outs Of Load Capacity

The cornerstone of selecting appropriate high strength drawer slides lies in understanding load capacity. This metric defines the maximum weight a drawer slide can support while maintaining optimal performance.

It’s vital to determine the combined static load (the drawer’s contents) and dynamic load (weight during opening and closing). Opt for a drawer slide with a capacity that surpasses these combined weights. This strategic approach guarantees longevity and prevents wear-induced hitches.

Exploring Types of Drawer Slides

Drawer slides are offered in various types, each meticulously designed to cater to specific applications and scenarios. The nuances of your project’s requirements will guide you in determining the most suitable type:

1. Ball-bearing Slides

These slides incorporate ball bearings to facilitate smooth motion. They are widely favored for frequently used applications and offer consistent movement and robust load-bearing capabilities. Ball-bearing slides can easily handle heavy loads, making them ideal for tool chests and industrial storage.

2. Roller Slides

Roller slides employ rollers for movement, an alternative to ball-bearing slides. These are well-suited for lateral applications like pull-out shelves or keyboard trays. Roller slides shine when lateral stability and extended reach are of the essence.

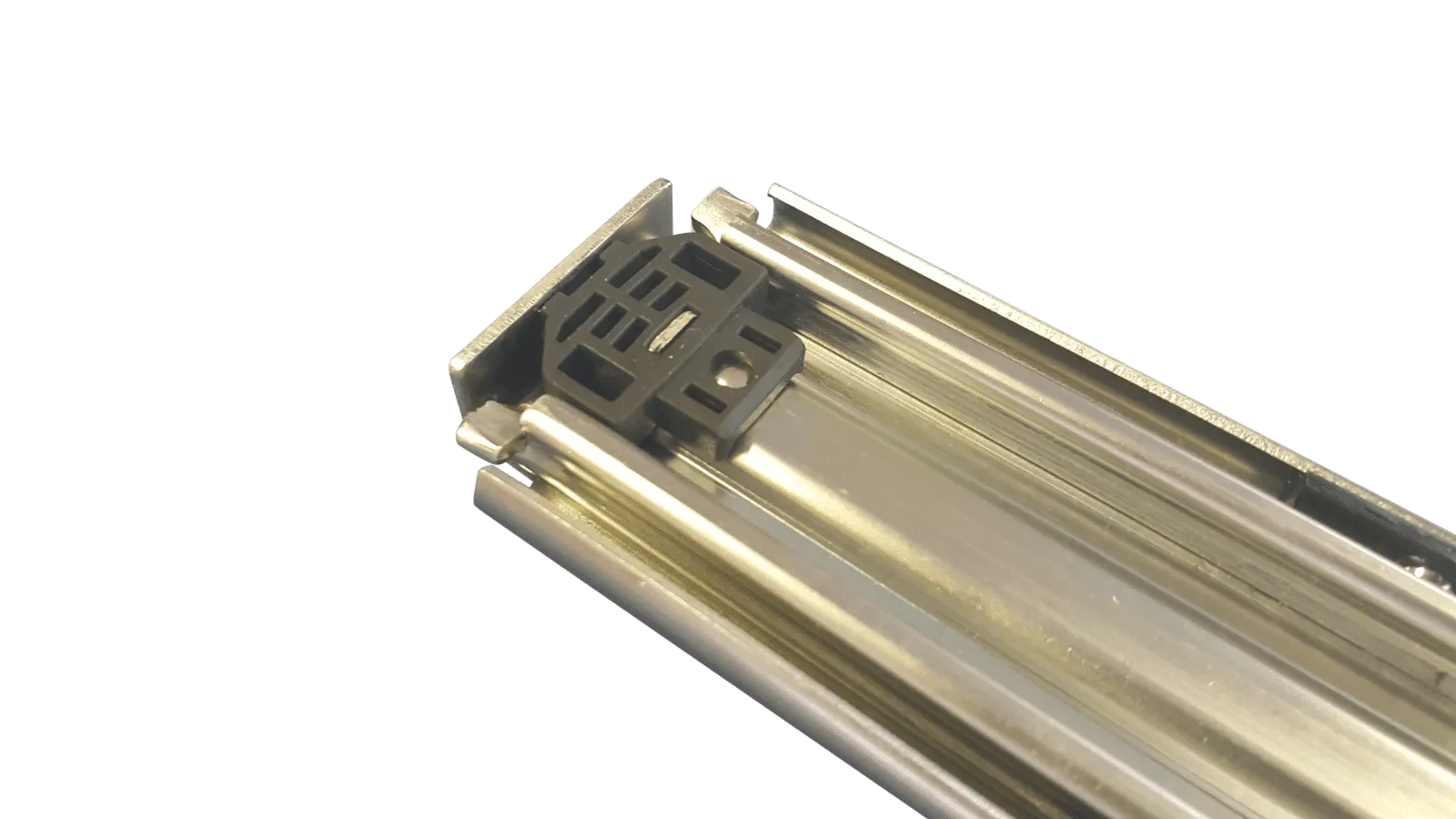

3. Telescopic Slides

Telescopic slides, composed of multiple sections that extend and retract, provide full access to drawer contents. This type finds its niche in space-constrained scenarios, offering controlled extension and smooth retraction while optimizing space usage.

4. Undermount Slides

They offer a sleek and modern appearance. These slides are frequently employed in contemporary furniture design and provide seamless functionality without compromising aesthetics.

Materials For Reliability

The material composing your drawer slides influences their performance and durability. Here are some of the best materials to choose from:

- Steel: Renowned for strength and robustness, steel drawer slides are the go-to choice for heavy-duty applications. Steel’s resilience benefits industries demanding high load capacities, such as manufacturing and machinery.

- Aluminum: Aluminum slides come to the fore if weight is a concern or if the environment entails moisture exposure. These lightweight slides resist corrosion, making them fit for marine or outdoor settings.

- Stainless steel: Applications where hygiene and resistance to corrosion are paramount, such as medical equipment or food industries, make stainless steel slides a reliable choice. The material’s durability and easy maintenance ensure smooth and clean operation.

Installation For Functionality

Meticulous installation is the bridge connecting the chosen drawer slides to optimal functionality:

- Mounting position: Decide between side-mounted and under-mounted slides. Side-mounted slides attach to drawer sides and cabinet walls, while under-mounted slides remain concealed under the drawer.

- Clearances: Accurate cabinet space and drawer dimensions measurements are vital. Ensuring the chosen slides fit snugly within your available space is pivotal.

- Extension length: Determine the degree of drawer extension you require. Full-extension slides grant complete access to drawer contents, whereas partial-extension slides offer controlled accessibility.

- Locking mechanisms: Assess whether your project demands locking mechanisms. These can keep the drawer securely closed or open when necessary, offering enhanced safety and convenience.

- Ease of installation: Opt for slides with comprehensive installation instructions requiring minimal specialized tools. The ease of installation ensures a hassle-free setup process.

Quality vs. Cost: Striking the Balance

Balancing the scale between quality and cost is a make-or-break occurrence regarding high-strength drawer slides. While cost-efficiency is a natural consideration, prioritizing quality yields benefits. Quality drawer slides ensure enduring performance, granting smooth and efficient gliding even with frequent use.

This proactive investment circumvents future maintenance or replacement costs, enhancing long-term value. Conversely, choosing cost-driven alternatives might lead to hidden expenses due to operational disruptions, breakdowns, and reduced productivity. Striking a harmonious balance entails an all-encompassing approach that acknowledges immediate budget constraints and quality’s enduring impact.

Considering Environmental Factors for Drawer Slides

The setting in which your drawers are installed can greatly influence the longevity and performance of their slides. Elements such as humidity, temperature, and corrosive substances can all play a part. Imagine a seaside home with salt-laden air or a chemical laboratory with potent substances; the drawers in these places require distinct considerations.

Material Selection

Moisture Concerns: Areas with heightened humidity or frequent moisture exposure, like bathrooms or coastal regions, require special attention. Opt for stainless steel or aluminum drawer slides in such conditions. Their inherent corrosion resistance can make them the champions of such environments.

Temperature Fluctuations: Whether it’s the sweltering heat of a workshop or the cold confines of a freezer room, drawer slides must persevere. Seek out materials proven to endure temperature swings without faltering.

Chemical Resistance: In spaces like laboratories or industrial sites, drawers might face splashes or fumes of chemicals. Here, durability relies on materials impervious to chemical erosion.

Through careful evaluation of these environmental nuances, you can align your choice of high-strength drawer slides with the specific challenges they’re bound to face.

The Grace of Soft-Close Mechanism

At its core, the soft-close feature is an ambassador of subtlety. Utilizing hydraulic or pneumatic prowess, it gently guides drawers to a quiet close, shielding them from the harsh jolt of slamming and the subsequent wear and tear. It’s the symphony of silence in the otherwise noisy orchestra of daily life.

Applications and Advantages

Home Settings: Imagine the calm ambiance of residential kitchens and bathrooms, where every sound is magnified. Soft-close slides are a boon, adding a touch of safety, especially where tiny fingers might get caught, and muffling noise.

Weight and Quality: Not all soft-close mechanisms are born equal. Dive deep into their specifications. Consider the weight they can manage and the quality of damping they offer. A drawer laden with heavy utensils demands a different kind of grace than one with light linens.

Warranty and Customer Insights: Your Decision Compass

When manufacturers stand by their products with extended warranties, it often reflects their confidence in their offerings. A longer warranty can serve as a beacon, guiding you towards products of superior quality and resilience.

Tapping into Customer Wisdom

Reviews and Testimonials: The digital age gives us a treasure trove of firsthand experiences. Scour reviews to glean insights into the actual performance, installation ease, and lifespan of the drawer slides you fancy.

Spotting Patterns: Beyond individual reviews, keep an eye out for patterns. If a particular issue crops up repeatedly, it’s not just a stray incident but a potential red flag.

Remember, merging the soft-touch elegance of a soft-close mechanism with the reassurance of warranty insights can dramatically refine your quest for the perfect high-strength drawer slides.

One Step Closer To the Right Decision

Choosing high-strength drawer slides involves a holistic evaluation of load capacity, slide types, materials, and installation requirements. By researching more about these facets, you’re well-equipped to make a selection that aligns with your project’s needs. Whether you’re working on a woodworking endeavor, industrial equipment, or specialized cabinetry, the proper choice of drawer slides contributes significantly to your creation’s overall success and satisfaction.