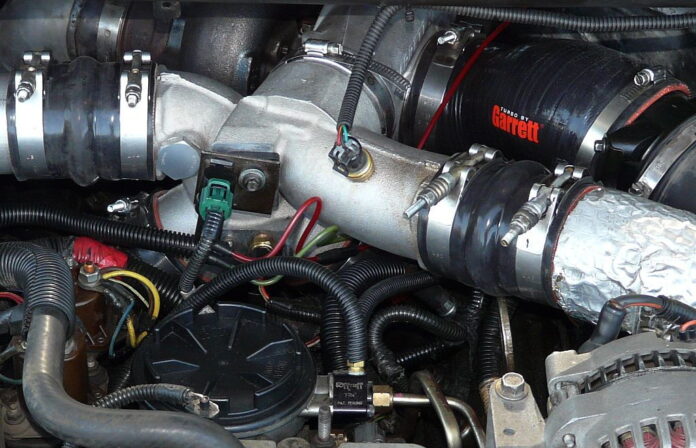

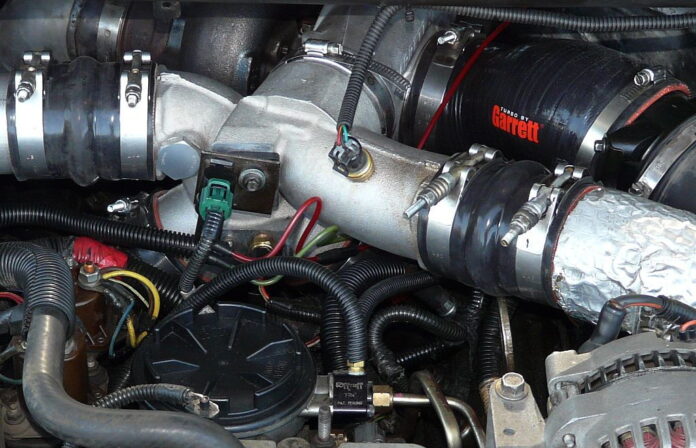

Leaks in the intercooler boots can be a common issue in the Ford 7.3 Powerstroke engine, often resulting in reduced performance and efficiency. Identifying and addressing leaks effectively is essential for maintaining the engine’s output and longevity. The intercooler plays a pivotal role in cooling the compressed air from the turbocharger, ensuring the engine receives the optimal mix of air and fuel. When intercooler boots, which connect the intercooler to the engine, begin to leak, they can compromise this process, leading to a drop in boost and a potential decrease in engine power.

Troubleshooting leaks within the intercooler system requires a systematic approach, starting with a visual inspection and then a pressure or boost leak test to pinpoint the exact location of the leak. Vehicle owners must understand the signs of a leaking intercooler boot, such as visible cracks, oil residue, or a notable change in engine sound. Pressure testing the system can confirm the presence of a leak by measuring the psi levels as air is forced through the intercooler circuit.

Key Takeaways

- Leaks in 7.3 intercooler boots decrease engine performance.

- Visual inspections and boost leak tests are effective diagnostic methods.

- A systematic approach is critical for proper troubleshooting.

Diagnosing 7.3 Intercooler Boot Leaks

Diagnosing 7.3 intercooler boot leaks is crucial for maintaining engine performance and efficiency. This involves performing tests and inspections to identify weak points in the turbocharging system.

Performing a Boost Leak Test

A boost leak test is a definitive method to confirm if there are leaks within the intercooler system. By using a boost leak tester—a device that introduces pressurized air into the system—one can listen for escaping air. Soapy water applied to intercooler boots can help by showing bubbles at leak sites.

Inspecting Intercooler Boots and Clamps

A thorough visual inspection of the intercooler boots and clamps can reveal cracks, tears, or loose fittings. Stock boots might degrade over time, leading to air leaks. It’s imperative to examine the CAC boots for signs of soot, which may indicate an air leak in the system.

Checking for Common Fail Points

Certain components are more prone to failure and should be examined closely. These include areas near the air intake, mass airflow sensor, and intake manifold. The crankcase vent can also affect the pressure if not sealed properly. Look for any unusual wear or degradation of rubber components.

Understanding Pressure and Leak Dynamics

Analyzing the system’s pressure behavior provides insights into potential leaks. During a pressure test, if the system fails to maintain the pressure or drops rapidly, it suggests a leak. Leaks can lead to a loss of power, efficiency, and unaccounted fuel ratios due to erroneous readings from sensors like the mass airflow sensor or EGT. It can also result in untuned conditions that further strain the engine components.

By following these steps meticulously, one can effectively locate and address issues related to 7.3 intercooler boot leaks.

Troubleshooting and Resolving Issues

Effective diagnosis and troubleshooting is vital when addressing issues with a 7.3 intercooler system. Precise steps must ensure that leaks are fixed, performance is optimized, and components are upgraded for better results.

Fixing Leaks and Replacing Damaged Parts

Inspecting the intercooler boots for any signs of damage, such as cracks or tears, is the first step in troubleshooting. If oil or coolant is present on the intercooler or piping, it might indicate a leak. These leaks often lead to turbo lag and reduced throttle response. Using a smoke machine or a pressure tester can help reveal the location of the leaks. Once the defective parts are located, they should be replaced immediately. High-quality replacements for 7.3 intercooler boots can ensure the issues don’t recur.

Adjusting for Optimal Boost Levels

Proper airflow and boost levels are critical for efficiently operating a Powerstroke diesel engine. Gauges like the EGT (Exhaust Gas Temperature) gauge can help monitor exhaust heat and ensure that boost levels are within the optimal range. Inspecting the boost tube and up-pipes for exhaust leaks is essential for low boost levels. Adjusting the fuel system, injectors, and nozzle to manage the air-to-fuel ratio can also significantly improve boost levels.

Upgrading to High-Performance Components

For those wanting to get the most out of their F-350 or similar models, upgrading to high-performance components can provide improved durability and performance under high heat and pressure conditions. Consider upgrading to silicone radiator hoses for better heat resistance. A lifetime warranty on certain parts can also offer quality assurance and longevity. It’s also worth checking the airflow sensor to ensure accurate readings, which is crucial for maintaining optimal turbo and supercharger performance.

Conclusion

Diagnosing and troubleshooting leaks in 7.3 intercooler boots is a critical maintenance task. It requires attention to detail and adherence to a systematic approach. Visual inspection and pressure testing are the primary methods to identify problematic areas. Upon detecting leaks, replacing worn boots or tightening clamps can restore the proper function of the intercooler system. Regular checks can prevent future issues, ensuring peak performance and longevity of the engine.