The Basics of Heat Transfer: Conduction, Convection, and Radiation

Understanding thermal sensors essentially begins with the principles of heat transfer, which governs how heat moves from one body or substance to another. The three primary mechanisms of heat transfer are conduction, convection, and radiation. Conduction occurs when heat energy is transferred through a material without the overall movement of the material itself. This process is highly effective in solids, particularly metals, where free electrons can easily transfer heat. For instance, if one end of a metal rod is heated, the heat travels to the cooler end through direct contact of particles, illustrating conduction in action.

Convection, on the other hand, involves the physical movement of fluid (liquid or gas) and occurs when there is a temperature difference within the fluid. Hotter, less dense fluid rises, while cooler, denser fluid sinks, creating circulation patterns. This principle is vital in various thermal sensing applications, particularly in climate control systems, where sensors measure the temperature of air streams to maintain desired environmental conditions. Radiation, the third mechanism, is the transfer of heat through electromagnetic waves. Unlike conduction and convection, it does not require a medium; this is how warmth from the sun reaches the Earth. Understanding these modes of heat transfer is crucial when assessing how thermal sensors function and respond to their environments.

Types of Thermal Sensors: Your Comprehensive Overview

There are several types of thermal sensors, each with unique characteristics and functionalities that cater to different needs and industries. Thermocouples, for instance, are widely used due to their broad temperature range and relatively simple design, consisting of two different metal wires joined at one end. When this joint experiences a temperature change, it produces a voltage that can be translated into temperature readings. RTDs or Resistance Temperature Detectors, are another popular choice, operating on the principle that a material’s electrical resistance changes with temperature. These sensors provide excellent accuracy and stability, making them suitable for demanding applications in labs and industrial processes.

Infrared sensors, which detect thermal radiation, allow for non-contact temperature measurement. They are particularly beneficial in situations where traditional sensors cannot be used, such as high-voltage equipment or moving machinery. Additionally, thermistors, which are temperature-sensitive resistors, are used in applications requiring precise temperature measurements at lower ranges. Each type of thermal sensor presents its own advantages and limitations, and choosing the right one depends not just on the required temperature range but also on factors like accuracy, response time, and environmental conditions.

The Technology Behind Infrared Sensors: Seeing the Invisible

Infrared thermal sensors represent a unique intersection of physics and technology, capable of detecting invisible thermal radiation emitted by objects. These sensors operate within the infrared spectrum, typically ranging from 0.7 to 14 micrometers. The core technology relies on the principle of Kirchhoff’s law, which states that a good absorber of infrared radiation is also a good emitter. Infrared sensors utilize materials like thermopiles or microbolometers to convert thermal radiation into an electrical signal that can be measured and interpreted.

The real advantage of infrared sensors lies in their capability to accurately measure temperature without direct contact. This non-invasive approach is not only safer in many industrial contexts but also speeds up measurements since there is no need to wait for the sensor to equilibrate with the object’s temperature. Applications abound, from monitoring electrical connections in power stations to detecting overheating in chemical plants. Moreover, advancements in digital signal processing and sensor miniaturization are further enhancing the accuracy, sensitivity, and versatility of infrared thermal sensing technology, paving the way for innovative applications.

Real-World Applications: Where Thermal Sensors Shine

In Industry: Enhancing Safety and Efficiency in Manufacturing

In the industrial realm, thermal sensors have become indispensable tools for enhancing both safety and efficiency in manufacturing processes. They play a crucial role in monitoring equipment safety by detecting overheating in motors, bearings, and electrical connections, which can prevent catastrophic failures and reduce maintenance descends. For example, thermal sensors can be integrated into machine components to provide real-time temperature data to operators, allowing for the implementation of proactive maintenance schedules based on predictive analytics. This leads to reduced downtime and increased productivity.

On the manufacturing floor, thermal sensors are also utilized in processes such as extrusion, molding, and surface tempering, where maintaining specific temperatures is vital for product quality. Sensors can ensure that materials are heated or cooled to the desired temperatures, leading to higher quality outputs and reduced waste from defective products. Furthermore, with the advancement of IoT technologies, the integration of thermal sensors into smart manufacturing systems has allowed factories to implement more sophisticated temperature monitoring solutions, increasing operational efficiency and energy management.

In Medicine: Revolutionizing Patient Care and Diagnosis

Thermal sensors are revolutionizing the medical field, aiding in patient care and diagnostics with their ability to provide accurate temperature measurements efficiently. Infrared thermometers, for instance, have become a standard tool in clinical settings, especially during the global health challenges posed by diseases like COVID-19, where rapid temperature screening became vital in infection control protocols. These non-contact thermometers quickly and accurately assess body temperature, allowing for immediate decisions around patient care.

Moreover, thermal imaging systems are increasingly used in various diagnostic applications, ranging from identifying areas of inflammation or poor blood circulation to detecting hidden tumors. By visualizing thermal anomalies within the body, healthcare professionals can obtain insights that traditional imaging techniques may not reveal. Furthermore, wearable thermal sensors, continuously monitoring body temperature, are emerging as essential in personalized healthcare, providing invaluable data that can alert patients and providers about potential health issues before they escalate.

In Smart Homes: Making Your Living Space More Intelligent

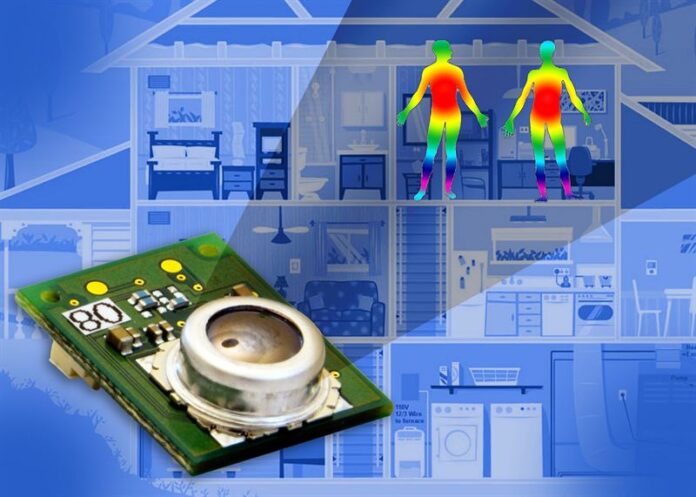

As the trend towards smart homes continues to grow, thermal sensors are becoming a crucial component in making living spaces more intelligent and energy-efficient. Smart thermostats incorporate thermal sensors to monitor ambient temperature, adjusting heating and cooling systems accordingly to maintain optimal comfort while minimizing energy consumption. These systems can learn residents’ behaviors, making automatic adjustments based on real-time data and historical trends, which not only provides convenience but also significantly lowers energy costs.

Additionally, thermal sensors support security systems within smart homes. Motion detectors utilizing thermal imaging can identify intruders by sensing heat emitted from their bodies, distinguishing between humans and pets or inanimate objects. This capability can enhance the overall effectiveness of alarm systems and provide homeowners with peace of mind. As technology advances, we’ll likely see further integration of thermal sensors in smart home devices, enhancing their capabilities and functionalities, promoting a more sophisticated living environment.

Choosing the Right Thermal Sensor: A Guide for Every Need

Criteria for Selection: Accuracy, Range, and Cost

Selecting the right thermal sensor demands a thorough understanding of various criteria, with accuracy, range, and cost being paramount. Accuracy indicates how closely a sensor’s measurement reflects the true temperature, and this requirement can vary greatly from one application to another. For example, aerospace or medical applications may require utmost precision, while industrial applications may allow for greater tolerance. Various calibration methods and sensor technologies can improve accuracy, but also tend to come at a higher cost.

The measurement range of a thermal sensor defines the temperatures it can accurately measure. While some applications may require sensors that operate at extreme low or high temperatures, others may operate within a narrower range. It’s crucial to choose a sensor that not only fits the application requirements but also has room for potential future needs. Cost, though sometimes overlooked, plays a critical role in decision-making. The cheapest option is not always the best in terms of performance and durability, and understanding the total cost of ownership, including maintenance, calibration, and replacement expenses, can provide a more comprehensive evaluation.

Custom Solutions: Tailoring Thermal Sensors to Specific Applications

In many cases, off-the-shelf thermal sensors may not meet the specific requirements of particular applications, necessitating the exploration of custom solutions. Tailoring thermal sensors can involve modifications to sensor design, material choices, and even software integration to accommodate specific environments or requirements. For instance, in medical settings, thermal sensors may need to be embedded within devices for precision monitoring, necessitating altered size or sensitivity specifications. Manufacturers may design sensors with unique casing that can withstand harsh conditions, such as extreme temperatures, moisture, or dust, ensuring reliable performance in demanding industrial environments.

Moreover, custom sensors can incorporate advanced technologies such as wireless communication for remote monitoring, integrating seamlessly into IoT ecosystems. As industries evolve and technology advances, the demand for tailored thermal sensing solutions will only increase, highlighting the importance of partnering with skilled suppliers who possess the expertise to deliver innovative solutions effectively.

Frequently Asked Questions: Expert Answers for Smart Buyers

A common question that arises regarding thermal sensors is, “What is the difference between contact and non-contact sensors?” Understanding this distinction is vital for efficient selection based on the intended application. Contact sensors require physical contact with the object whose temperature is being measured, providing highly accurate readings but potentially altering the temperature of the object or being impacted by external conditions. On the contrary, non-contact sensors, predominantly infrared, offer convenience and speed in applications where contact is impractical or dangerous.

Another frequently asked question pertains to battery life and power consumption of these devices. With the increasing reliance on portable and wireless thermal sensors, longer battery life and lower power consumption become crucial features to consider. Sensors powered by advanced technologies often boast remarkable battery efficiencies, enabling them to operate for extended periods without the need for frequent changes or recharges. Understanding these specifications can significantly enhance the performance and reliability of thermal sensing solutions, enabling informed decision-making.

Future Trends in Thermal Sensing Technology: What Lies Ahead?

The Rise of Wearable Tech: Taking Thermal Sensing to New Heights

The emergence of wearable technology is shaping the future of thermal sensor applications. With an increasing emphasis on health and fitness monitoring, the integration of thermal sensors into wearable devices offers a new frontier for both health tracking and personalized medicine. Thermoregulation, monitoring body heat during exercise, or detecting early signs of fever are just a few applications fueling research in this area. As technology progresses, wearables equipped with sophisticated thermal sensors could soon provide unprecedented insights into individual health metrics, enhancing preventive care and improving overall wellness.

Moreover, wearable thermal sensors can seamlessly integrate with AI and machine learning to analyze vast datasets, providing meaningful feedback to users and healthcare providers on health status and trends. As these technologies converge, the potential for thermal sensors to contribute to everyday health management is immense, promising a future where individuals take greater ownership of their health through proactive, data-driven decisions.

Cutting-Edge Innovations: Nanotechnology and Its Impact on Sensors

Nanotechnology is quickly becoming a transformative force in the field of thermal sensors, leading to the development of novel materials and enhanced device capabilities. At the nanoscale, materials can exhibit unique thermal properties, resulting in sensors with improved sensitivity, faster response times, and greater accuracy than their traditional counterparts. Innovations such as graphene-based sensors and nanostructured thermoelectric materials have demonstrated exceptional performance, enabling the detection of minute temperature variations and facilitating applications that require precision.

As the field of nanotechnology continues to evolve, we can expect thermal sensors to become smaller, lighter, and more capable, pushing the boundaries of what is possible in temperature measurement. This could enable new applications in industries ranging from aerospace to biomedical engineering, where space and weight limitations previously hindered sensor deployment.

Sustainability and Efficiency: The Green Future of Thermal Sensors

As global awareness of sustainability and environmental responsibility increases, so too does the call for thermal sensor technology to adapt and contribute to greener practices. Eco-friendly materials and manufacturing processes are now at the forefront of sensor development, focusing on reducing environmental impacts while providing efficient performance. Thermal sensors, when integrated into building management systems, can optimize energy use in heating, ventilation, and air conditioning (HVAC) systems, significantly cutting energy costs and lowering carbon footprints.

Furthermore, advancements in power generation and harvesting, including development in thermoelectric systems, could position thermal sensors as integral components of energy-efficient solutions. By capturing waste heat and converting it into usable energy, these sensors can enable self-sustaining operation, promoting the idea of closed-loop systems in various applications. The pursuit of sustainability in thermal sensing technology not only meets consumer demand for eco-friendly products but also aligns with global efforts to combat climate change and improve energy efficiency across sectors.