If someone told you ten years ago that a robot would be welding parts on your production line, you might’ve laughed it off as science fiction. Fast forward to today, and robot welders are not only real – they’re quietly reshaping the way modern manufacturing works.

But is it just a tech trend, or could a robot welder actually make a difference to your business?

What Exactly Is a Robot Welder?

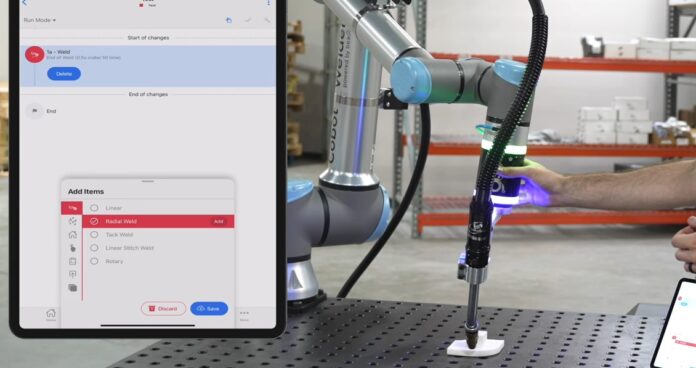

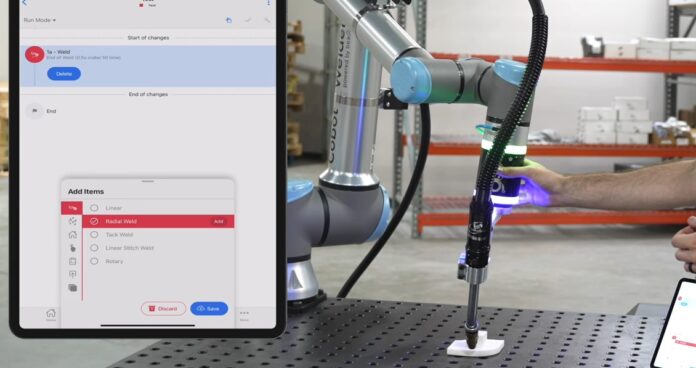

Let’s start with the basics. A robot welder is an automated system designed to carry out welding tasks. Once it’s programmed, it can work continuously, delivering clean, consistent welds – all without needing a break. These machines are often used in industries like automotive, aerospace, agriculture, and even furniture manufacturing.

They’re precise, efficient, and surprisingly adaptable.

Modern robot welders use sensors and AI-enhanced systems to adjust in real time, detecting variations in materials or environmental conditions. This means they can handle more complex welding situations than ever before, closing the gap between automated and human performance.

Why More Businesses Are Making the Switch

You don’t have to be a global car brand to benefit from automation. Here’s why smaller and mid-sized manufacturers are now getting on board:

- Faster turnaround times – Robot welders can handle large batches without slowing down, helping you meet tight deadlines.

- Fewer mistakes – Every weld is performed exactly as programmed, meaning less rework and fewer defects.

- Lower labour strain – Repetitive welding can take its toll on human workers. Robots reduce the physical strain, leaving your team to focus on the skilled or custom jobs.

- Better margins – Once the initial investment is covered, a robot welder often pays for itself by lowering production costs and increasing capacity.

In addition, robot welders contribute to a safer workplace. By removing human workers from the immediate welding environment, you reduce exposure to heat, fumes, and UV light. For many safety-conscious businesses, this is a major win.

But What About My Skilled Welders?

That’s a great question – and it’s where robot welders really shine. They’re not here to replace skilled professionals. Instead, they act as a support system.

While the robot handles repetitive or high-volume jobs, your experienced welders can focus on the tricky stuff – repairs, prototypes, custom work, or anything that needs a human touch. It’s about combining the best of both worlds.

In fact, some companies report that robot welders actually enhance their human teams. With robots handling the grunt work, welders have more time for training, quality control, and creativity. And for younger workers entering the field, this tech-forward environment can make the trade more appealing.

Is It Worth the Investment?

The cost of a robot welder has dropped significantly in recent years, and there are even leasing options available. If you regularly take on repeat orders or run into labour bottlenecks, it could be well worth exploring.

And don’t forget – having a robot welder can also make your business more attractive to potential clients. Faster turnaround, consistent quality, and modern tech can all give you a competitive edge when bidding for contracts.

There’s also long-term flexibility to consider. Many modern robotic systems are modular, meaning they can be reprogrammed or retrofitted to take on different types of welding, or even entirely new tasks, as your needs evolve.

A Competitive Edge in a Tight Market

In today’s competitive manufacturing landscape, standing still isn’t an option. Companies are under constant pressure to deliver faster, improve quality, and control costs — all while dealing with labour shortages and increasing demand for customization. This is where robot welders truly shine.

By automating repetitive welds, you free up valuable time and resources. This can help you respond more quickly to market changes, scale production when new contracts come in, and offer consistent quality that keeps clients coming back. With more industries embracing automation, having a robot welder on your team could become a baseline expectation, not a novelty.

Customers and partners alike increasingly view automation as a mark of innovation and reliability. When they see that your business invests in modern tools like robotic welding, it signals professionalism, efficiency, and a forward-thinking approach. That perception can go a long way in building trust and securing long-term relationships.

Even for custom or low-volume shops, the right robotic setup can add a layer of flexibility that was once unthinkable. From small batch jobs to specialized fabrication, modern systems can pivot faster than ever before, offering a level of agility that keeps your business resilient — no matter the challenge.

Training and Integration: Easier Than You Think

One concern often raised by business owners is the learning curve. But here’s the good news: training staff to operate a robot welder is getting easier. Most manufacturers offer intuitive software and hands-on training, and some systems can even “learn” tasks by observing a human welder once.

Integration into your workflow is also less disruptive than you might expect. Many systems are designed to fit into existing production lines, with minimal downtime for setup. Once running, they can operate around the clock with only minimal supervision.

Final Thoughts

The idea of introducing a robot welder to your team might feel like a big leap – but it could be the smartest move you make this year. Whether you’re expanding your workshop or just want to future-proof your processes, automation is becoming more of a necessity than a luxury.

And who knows? You might just find that your new robot colleague becomes the most consistent team member you’ve ever had.

If you’re curious about what that journey could look like, this guide breaks down the benefits, costs, and real-world applications of robot welding.